For decades, emission control systems have been studied and developed to encompass a vast array of engines and vehicles. With such an expansive selection, these various types of emission control systems can be confusing and complicated when it comes to the needs and demands of running a fleet. However, by fully understanding the basics and benefits of control systems, you can bring the highest possible success and efficiency to your fleet.

What Are the Different Types of Emissions and How Do T hey Work?

hey Work?

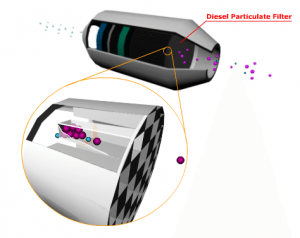

- DPF – Diesel Particulate Filters trap and remove particles and various matter from diesel exhaust. These particles are often considered soot and after 2007, all diesel engines were built with DPF systems to eliminate 90 percent of the soot released into the air.

With both passive and active regeneration, the diesel particulate filter is cleaned by burning off the soot that built up in the filter. By burning it at a high temperature, the soot is reduced to nothing but a harmless ash residue.

- SCR – Selective Catalytic Reduction injects a liquid-reluctant formula through the catalyst of a diesel engine, which enters the engine’s exhaust stream. This system is one of the most advanced active emissions control technology systems in use today.

The benefits of SCR are plentiful. No only can SCR reduce the amount of nitrogen oxide released into the air by up to 90 percent, but it can also be combined with a diesel particulate filter to significantly reduce the amount of particulate matter emissions as well. Lastly, commercial fleets have reported a 3-5 percent gain in fuel economy by utilizing SCR systems.

- DOC – Diesel Oxidation Catalysts are devices that reduce emissions by means of exhaust after treatment. Once the hot diesel exhaust flows through a honeycomb structure, the oxidized metal coating creates a reaction that breaks down pollutants. Their simplicity and low maintenance requirements make them one of the most commonly used emission control systems.

DOCs are verified by the Environmental Protection Agency to reduce the particulate matter in emissions by 20 to 40 percent. DOCs can also reduce hydrocarbons by 40 to 75 percent and carbon monoxide by 10 to 60 percent.

- CCV – Closed Crankcase Ventilation Systems are employed on post-2010 vehicles to comply with Environmental Protection Agency emission regulations to reduce and fully eliminate crankcase emissions, or harmful gasses.

By utilizing a closed crankcase ventilation system, harmful gasses are reduced by nearly 100 percent. It improves air quality in the passenger compartments and can increase fuel efficiency.

Why Are Emission Control Systems Important?

Before strict  emission regulations were implemented in 2007, harmful gasses, destructive particles, and dangerous matter were released into the air and caused an array of problems. By employing regulations on the emissions of diesel engines, the discharge of noxious gasses is limited.

emission regulations were implemented in 2007, harmful gasses, destructive particles, and dangerous matter were released into the air and caused an array of problems. By employing regulations on the emissions of diesel engines, the discharge of noxious gasses is limited.

At FleetServ, professionals are standing by to help you outfit your fleet with the best emission control systems possible. We offer every part necessary for proper emissions control and can assist fleet managers in developing compete emission strategies for any fleet. Call or click today for more information.

photo credit: Peterbilt Exhaust via photopin (license)